FROM DESIGN TO FACTORY ACCEPTANCE: HOW INDUSTRIAL CONTROL CABINETS ARE BUILT

Designing and building an industrial control cabinet is a structured process involving engineering, design specifications, wiring standards, component selection, and testing. This guide walks through how control cabinets move from initial concept to Factory Acceptance Test (FAT) and installation.

This post explains the major steps:

- Designing the Cabinet

- Building the Cabinet in the Factory

- Quality Checks & Factory Acceptance Testing (FAT)

- Challenges & How They are Solved

- Key Project Success Factors

- Conclusion

1. Designing the Cabinet

A. Gathering Design Information

- Control philosophy

- P&ID diagrams

- I/O List (digital, analog, special signals)

- PLC hardware selections (brand, modules, redundancy)

- Single-line diagrams

- Customer specifications

- Environmental conditions (temperature, dust, humidity, etc.)

All information is consolidated into engineering documentation, which forms the basis for cabinet layout and internal component selection.

B. Creating the Functional Design

- System architecture

- PLC I/O mapping

- Panel layout drawings

- Loop diagrams

- Cable block diagrams

- Bill of materials (BOM)

2. Building the Control Cabinet

A. Panel Wiring & Assembly

- DIN rail mounting

- Power supply wiring

- Terminal strip installation

- Grounding & shielding practices

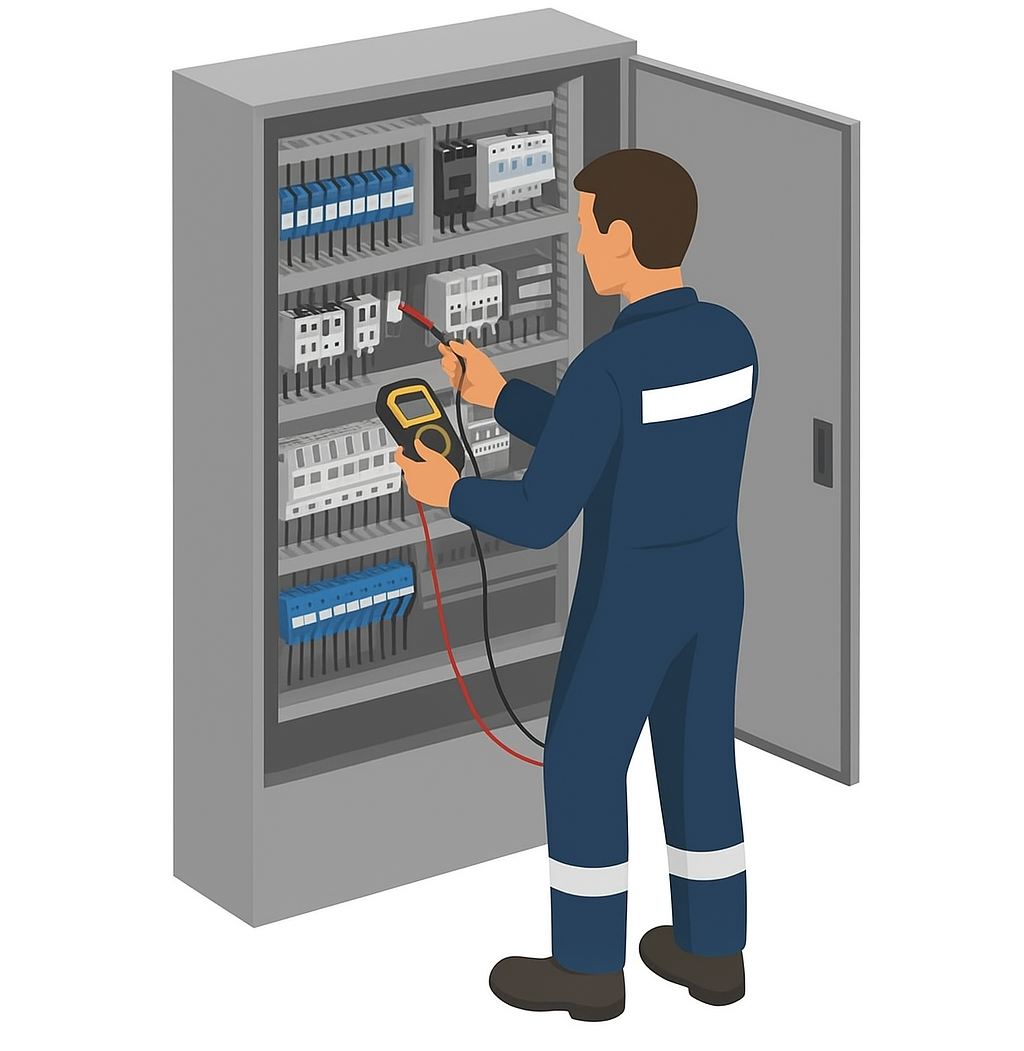

3. Factory Acceptance Testing (FAT)

A. Internal Testing

- Point-to-point wire continuity testing

- Power ON checks

- PLC online test (inputs & outputs)

- Loop testing (simulation of signals)

- Verification of naming & labeling

B. Witness FAT with Client

- Customer validation of wiring & labeling

- Functional checks

- Simulation of failure conditions

- Final punch-list corrections

4. Common Challenges & How They Are Solved

| Challenges | Solutions |

|---|---|

| Inaccurate I/O or design information | Strong revision control & customer reviews |

| Missing components or late procurement | Early BOM finalization & supplier tracking |

| Wiring congestion | Clear routing, labeling & trunking layout |

| Late design changes | Version management, change control workflow |

| Client expectations mismatch | Regular design meetings & milestone reports |

5. Key Factors Influencing Project Success

- Clear documentation

- Good communication with client

- Early procurement

- Accurate schematics

- Strong internal testing before FAT

6. Conclusion

Building a control cabinet is far more than mounting components — it is a highly organized engineering process. Every stage must be carefully executed to ensure safety, reliability, and compliance.

A well-designed and well-tested cabinet reduces downtime, improves plant reliability, and ensures a smooth commissioning phase on site.